PLACEBO FABTECH PVT. LTD; is a one-stop-solution for all building requirements of varied customers. Our pre engineered steel buildings are uniquely designed and fabricated to suit your requirements. Built strictly following the international standards, these buildings consist of different components, meticulously designed to be compatible to each other. The fabrication of these components is carried out in factory under strict quality control as per detailed shop drawing. These components are transported to end user’s site with proper markings and assembled at the project site as per erection drawings. We cater to industrial, commercial and institutional requirements and provide enhanced speed in delivery and erection. We also provide flexibility in expansion and withstand severest weather conditions to deliver the best of pre-engineered solutions. These buildings are available in large multidimensional spans; lean to roof at all required heights and side claddings. They feature a structural steel framework of primary and secondary members (rigid frame, beams, purlins and grits, trusses and columns) on to which cladding and roofing components are attached. The plant is equipped with high precision CNC machines to fabricate and supply quality-replete steel buildings.

With the most innovative approach towards the modern day infrastructural needs across the country, PLACEBO FABTECH is handling every project with minute details following international standards with latest technology. PLACEBO FABTECH expertise rests in delivering flawlessly accurate engineering excellence within committed time frame to ensure timely completion of the projects by our esteemed clients. PLACEBO FABTECH fabricates steel structures from plates and rolled sections such as Columns, Beams, Bracings, Top Girders, Box sections conforming to technical standards and specifications under IS, ASTM, BS, EN and other global standards monitoring organizations, guaranteeing robustness and durability for power plant, steel plant and Railway Bridges. PLACEBO FABTECH goes beyond its expertise in structural fabrication to take erection work with the vision of emerging as a professional. The well trained and committed team of structural engineers and workers manage the erection work at site adhering best quality standards with utmost safety norms. PLACEBO FABTECH team plans and executes the erection of structure as per the sequence and within committed time frame to achieve customer satisfactions in all respect.

Some of the distinct advantages include:

- Durability – weather resistant, earthquake resistant

- Value – Low initial investment, low maintenance costs

- Environment friendly – All the materials can be recycled

- Flexible – Easy to expand, easy to setup and change

- Faster – Reduced construction time

- Aesthetics – Gives the engineer enough flexibility to create unique structures

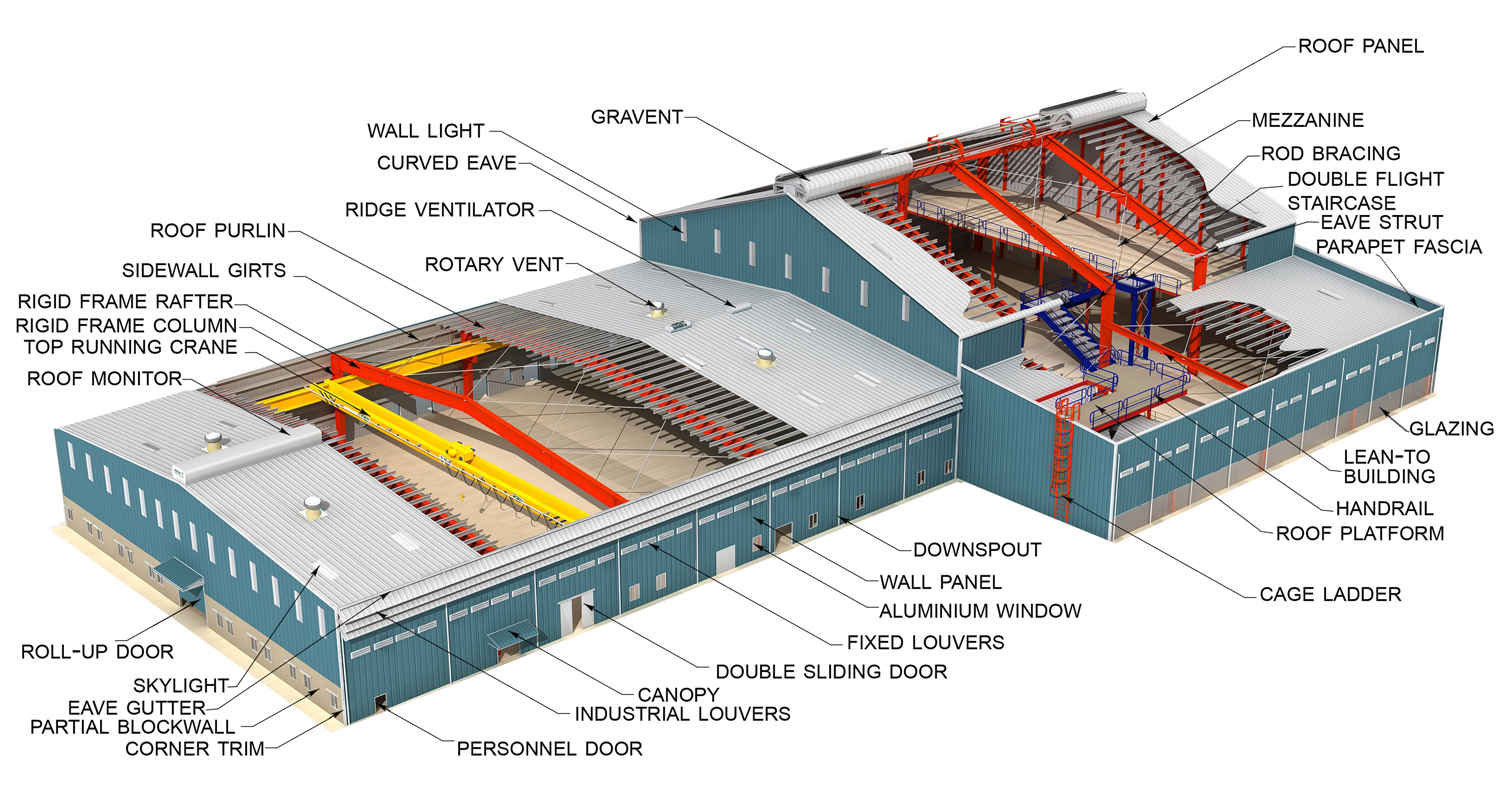

Following are the components used by PFPL for constructing steel buildings.

Main FrameRigid steel frames of the building are mainly considered as the Main Frames of PEB. PEB rigid frame comprises of tapered columns and tapered rafters (the fabricated tapered sections are referred to as built-up members). The tapered sections are fabricated using the state of art technology wherein the flanges are welded to the web. Splice plates are welded to the ends of the tapered sections. The frame is erected by bolting the splice plates of connecting sections together.

Purlins, Grits and Eave StrutsPurlins, Grits and Eave Struts are secondary structural members used to support the wall and roof panels. Purlins are used on the roof; Grits are used on the walls and Eave Struts are used at the intersection of the sidewall and the roof. Secondary members have two functions: they act as struts that help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads, and they provide lateral bracing to the compression flanges of the main frame members thereby increasing frame capacity.

Panels and InsulationPanels used for sheeting purpose are generally of ribbed steel sheets used as roof and wall sheeting, roof and wall liners, partition and soft sheeting. The steel sheets are generally produced from steel coils having thickness 0.5 mm to 0.7 mm high tensile stress..

Why choose PLACEBO FABTECH ?

- Stringent quality systems

- Faster cycle times

- Value – engineered solutions

- Continuous product improvement

- International presence and local service

- Trustworthy after sale service

- Comprehensive and detailed engineering output

- Attention to detail

- Thus, we provide a complete and the most trustworthy economical Structure solutions under one roof.

Components of Pre Engineered Buildings

Pre Engineered Buildings are Steel Structures built over a structural concept of:

- Primary Framing System

- Secondary Framing System

- Roof Sheeting

- Wall Cladding

- Accessories

- Primary Framing System

- Primary framing consists of all structural elements which transfer load to the foundation and comprise of:

- Rigid Frames

- End Wall Frames

- Wind Bracing

- Crane Brackets

COMPARATIVE STUDIES

| Evaluation Criteria | Peb Building | Concrete Building |

|---|---|---|

| Fabrication | Precise fabrication: Members fabricated in a controlled environment and up to 50% saving in fabrication time on site. | Fabrication done on site; Requires building the reinforcement cage and shuttering work prior to pouring. |

| Delivery and Logistics | Can be delivered in desired sequence anywhere in the world. | Might have to build batch plant on site if site is secluded or huge. |

| Installation Time | 50% saving in construction time. Fast Installation with no idle time. | Slow and time consuming: The contractor will have to wait for the previous cast to harden (14-28 days) before being able to cast next batch. |

| Quality | Quality of steel is guaranteed because

|

Many factors lead to quality deterioration

|

| Cost | Savings of 10%-15% for large span steel building. | Construction cost is high at site. |

| Industrial Applications | Saving on maintenance cost: Can easily handle equipment such as multiple cranes within building. Sways can be controlled. Precision can be achieved during installation. | Heavy equipment usage such as cranes is limited. |

| Commercial & Infrastructure Applications | Better aesthetics and longer spans can be achieved using steel as building component. | Limited designs are possible with concrete. |

COMPARISON BY APPLICATIONS

FACTORIES

| Options | Cost of Construction | Speed of Construction | Ease of Construction |

|---|---|---|---|

| PEB | Most Economical | Fastest | Most Simple |

| Concrete | Less Economical | Slowest | Cumbersome |

WAREHOUSES

| Options | Cost of Construction | Speed of Construction | Ease of Construction |

|---|---|---|---|

| PEB | Most Economical | Fastest | Most Simple |

| Concrete | Less Economical | Slowest | Cumbersome |

MALLS & RETAIL SHOPPING CENTERS

| Options | Cost of Construction | Speed of Construction | Ease of Construction |

|---|---|---|---|

| PEB | Economical | Fastest | Most Simple |

| Concrete | Most Economical | Slowest | Most Cumbersome |

RECREATIONAL BUILDINGS

| Options | Cost of Construction | Speed of Construction | Ease of Construction |

|---|---|---|---|

| PEB | Economical | Fastest | Most Simple |

| Concrete | Most Economical | Slowest | Most Cumbersome |

STEEL VS CONCRETE

| Evluation Criteria | Peb Building | Concrete Building | Steel Advantage |

|---|---|---|---|

| Building Dimensions |

|

|

12%-50% Cost saving for long span steel building |

| Fabrication |

|

|

90% saving in fabrication time on site. |

| Delivery and Logistics |

|

|

Capital Investment saving. |

| Erection Time |

|

|

50% saving in construction time. |

| Industrial Applications |

|

|

Saving on maintenance cost. |

| Quality | Quality of steel is guaranteed because

|

Many factors lead to quality deterioration

|

Less time is spent to maintain steel quality. |

| Cost |

|

|

– |

| Modulability & Scalability |

|

|

Lower modification cost. |

| Error Modification |

|

|

– |

| Consistency and Reliability |

|

|

– |

| Seismic Effect |

|

|

– |

| Ductility |

|

|

Steel building requires less costly safety measures. |