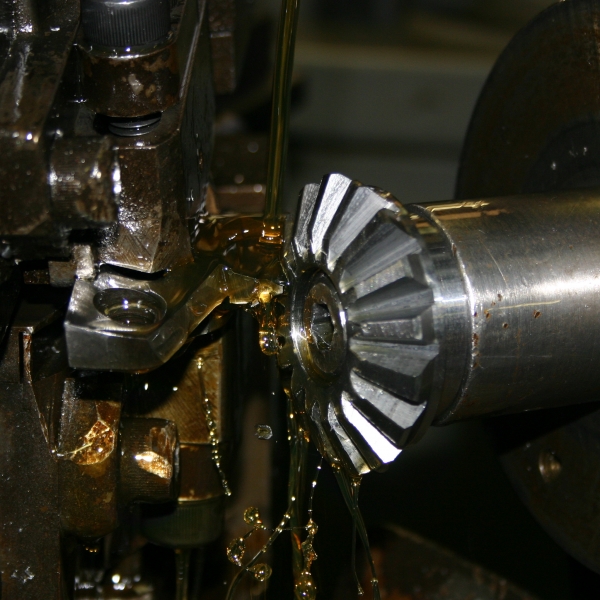

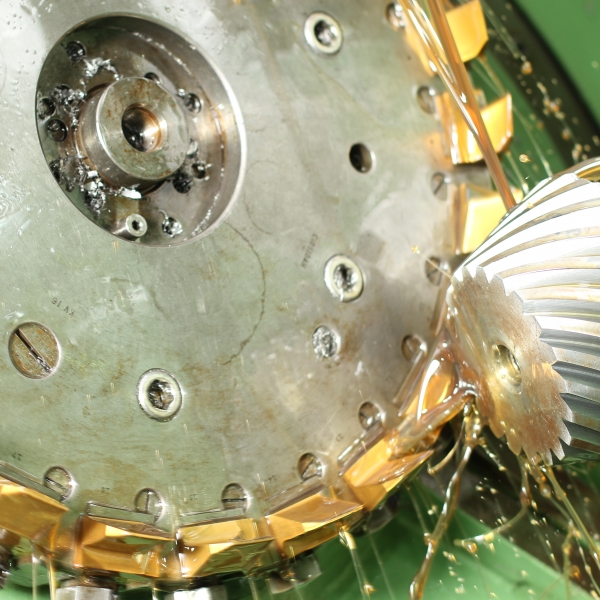

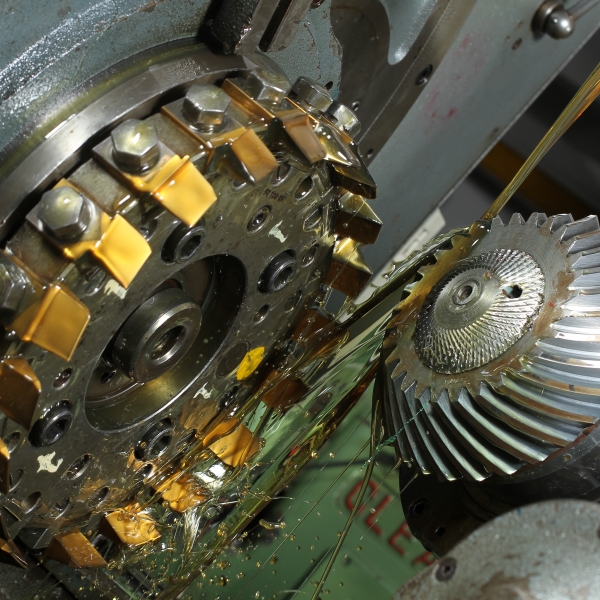

We have developed and manufactured over 1000 spiral Bevel Gear ratios. We have state of the art world proven CNC & Conventional machines from Gleason Works, USA. Gears are generated on Gleason summary following Five Cut Method. All gears are cut on gear cutting summary developed with sophisticated software. Each job is checked at soft stage to ensure bearing contact is generated for better lift and noise free gears. We are equipped to satisfy our discerning customers not only by offering standard route of manufacturing but also through our ability to develope indigenously Spiral Bevel Gears. Finished goods are inspected as per specifications provided by Customer / International Standards. Highest level of quality is possible by imposing stringent measures starting from receipt of forgings to packaging stage. Tooth spacing, contact pattern noise level and backlash checks are performed using Gleason Testers and other related equipment. Finally it is the obsession with quality that has earned PLACEBO the privilege to supply gears to the OEM and various clients.